Compression adjustment

>High/Low Speed Compression Adjustment Valve (H/L COMP)

>22 levels of high-speed damping adjustable

>17 levels of low-speed damping adjustable

The DK-68 R shock absorber is a next-generation product developed by K-MAN, built on years of racing experience and technological expertise. Its core feature lies in the innovative design that connects the nitrogen reservoir with the hollow piston rod: during compression and rebound, the damping oil circulates between the reservoir and the hollow rod, while both components are positioned at the upper section of the shock absorber. This layout effectively prevents damage to the piston rod from gravel and debris during high-speed racing. In addition, the integration of hydraulic compression and rebound bump stops greatly enhances the shock absorber’s impact resistance under extreme racing conditions. The DK-68 R made its debut at the 2025 Silk Way Rally, where it was fitted to three Kamaz Master trucks and contributed to the team’s sweeping victory of first, second, and third place overall. Beyond truck-class applications in the Dakar Rally, the DK-68 R can also be adapted for T1-class vehicles, delivering stable and outstanding damping performance for the most demanding competitions.

>High/Low Speed Compression Adjustment Valve (H/L COMP)

>22 levels of high-speed damping adjustable

>17 levels of low-speed damping adjustable

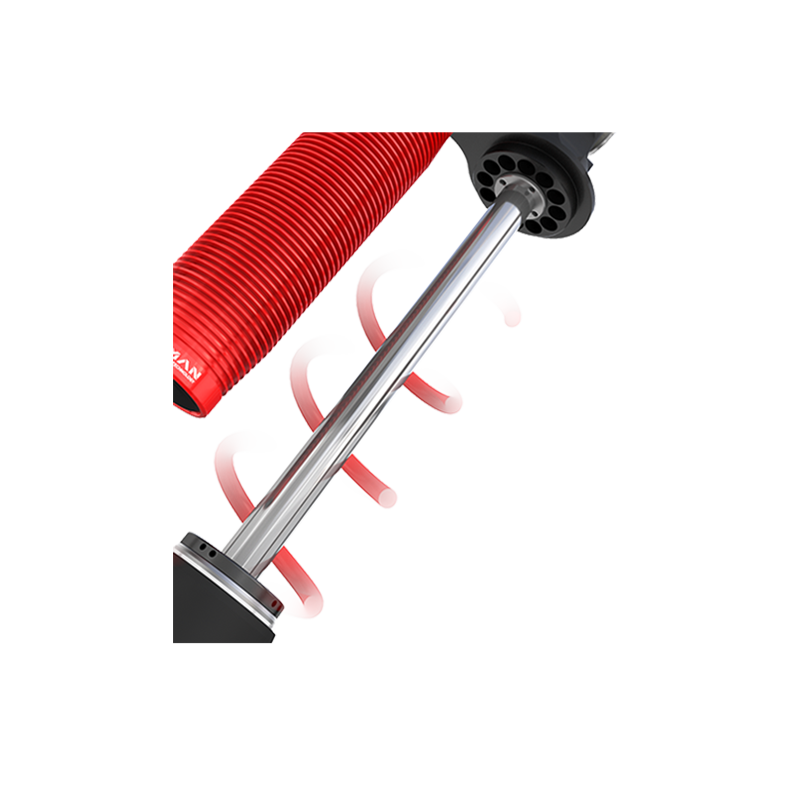

Piston rod

>Three polishing and three plating surface treatment technology

>Hardness greater than HV1000

>K-MAN Overseas R&D Center Design

>Dust seal combined oil seal DU design

>Reverse limiting structure design

>provide comfortable compression damping and progressive compression damping

>drive in a very comfortable way without the damper bottoming out

>drive in a very comfortable way without the damper bottoming out

>Gradually absorb larger impact energy

>Provides controllability and comfort under extreme conditions

Applicable models

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.